Alena Lochmanová

Office manager

Zákaznická linka

(Po-Pá od 8.00 - 16.30):

+420 721 737 697

info@ampersavings.cz

Datová schránka:

gu5rh2e

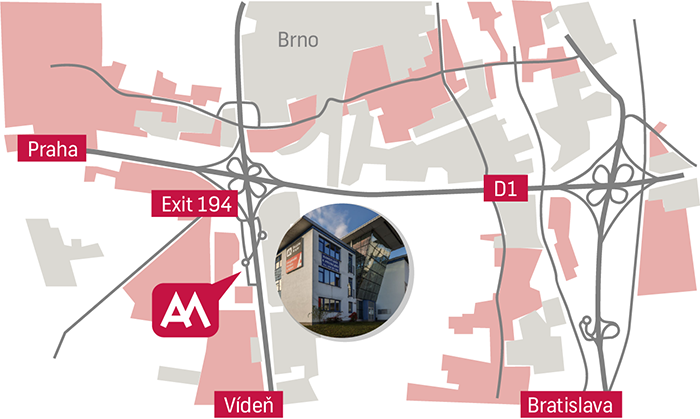

Sídlo společnosti a kanceláře v Brně:

Vídeňská 134/102

619 00 Brno - Dolní Heršpice

Kanceláře v Praze:

Pobřežní 620/3

186 00 Praha - Karlín

Obchod:

obchod@ampersavings.cz

Dispečink:

dispecink@ampersavings.cz